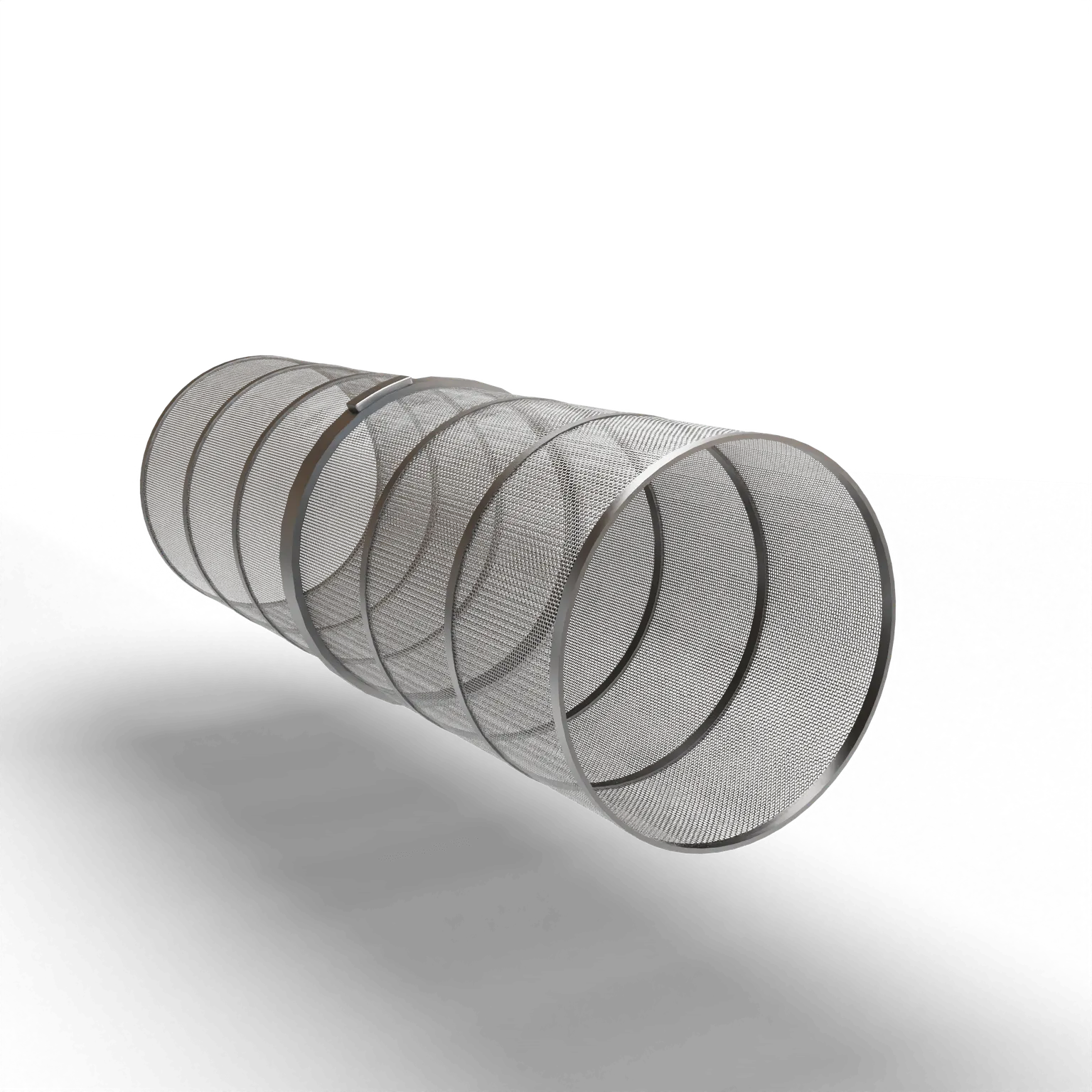

The widest range of applications in ultrasonic screening thanks to unique technology

Whether classifying, protective screening, dedusting or cleaning. Thanks to the patented process, the range of applications for the flexibly applicable ultrasonic systems are limitless.

Tumbler screening machines

Vibration screening machines

Protective Sieves

Laboratory Sieves

More

May we help you in finding a solution?

Get in contact with an ultrasonic specialist today.

Your advantages with our ultrasound at a glance

Whether as a retrofit or for your new machine or plant, the system is the ideal complement.

Artech Ultrasonic Artech Ultrasonic | Alternative Ultrasonic | Alternative Methods | |

|---|---|---|---|

| Throughput | High | High | Low-Medium |

| Separation efficiency | High | High | Low-Medium |

| Clogging tendency | Low | Low | High |

| Risk of contamination | Low | Medium | Medium-High |

| Versatility of application | High | Medium | Low |

+400%

Depending on the product, machine and sieve mesh, our ultrasound is capable of increasing throughput by up to four times.

+30

Already more than 30 screening machine manufacturers worldwide rely on our ultrasonic components.

0

Our components are located outside the sieving area. For you, this means 0 risk of contamination.

Why ultrasound is worth your investment

Whether as a retrofit or for your new plant or system, Artech ultrasonic is the optimal addition.

No tuning of the sieve geometry necessary = Maximum versatility

Thanks to the patented frequency variation method with automatic search of the optimum operating point, any sieve geometry can benefit from ultrasonic support. For you, this means maximum flexibility and all this with the same system.

Without product contact to the optimum sieving result

The components are located outside the sieving area. Thus, the risk of contamination can be prevented from occurring.

Less is more

With the use of ultrasound, the sieving area can be significantly reduced compared to alternative methods, since ultrasound allows more product to be sieved per area. This is essential, especially in the additive manufacturing sector, to build compact solutions.

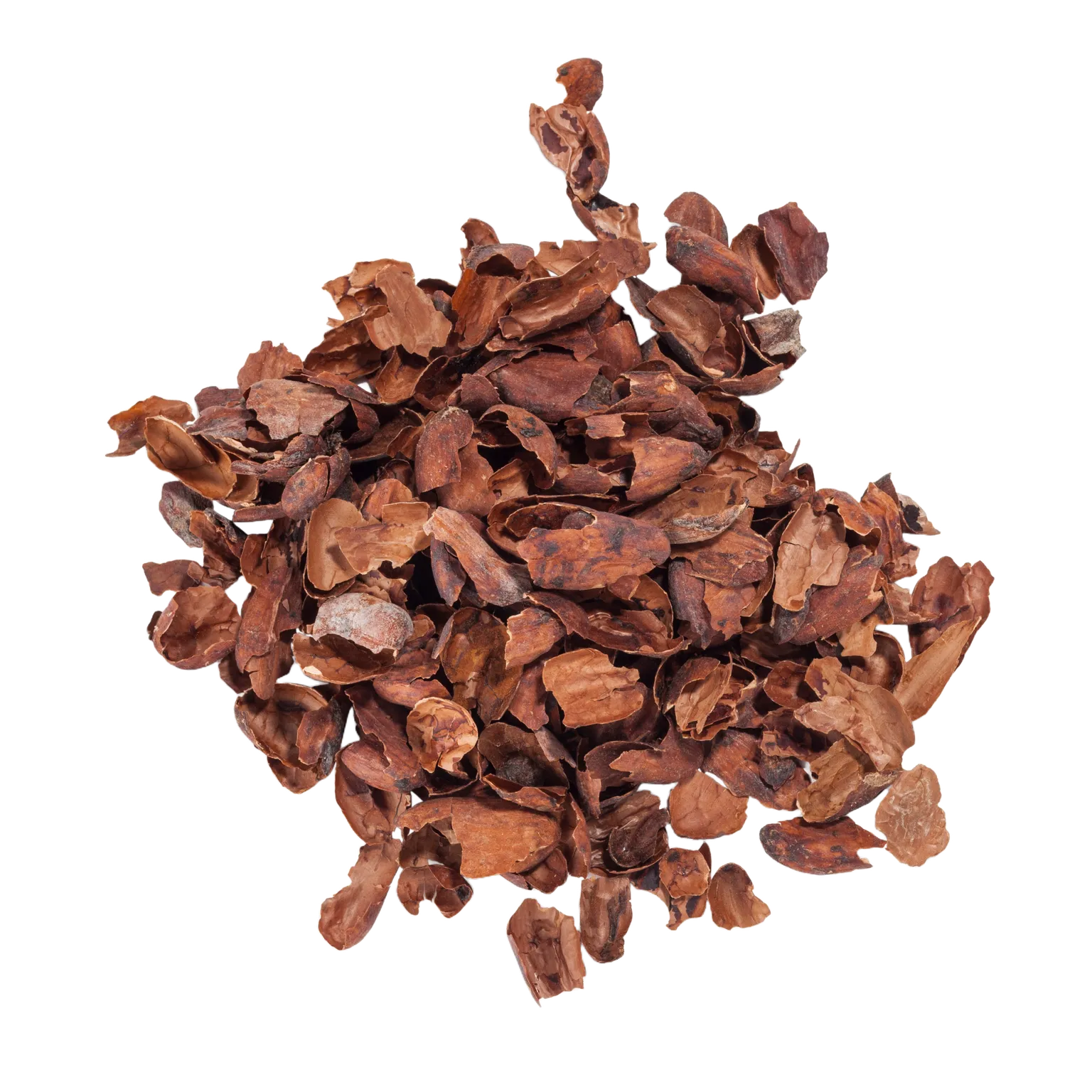

From metal powder to flour. Your industry is our industry

Additive Manufacturing

Whether powder preparation or powder recovery. With ultrasound, additive manufacturing reaches a new level of efficiency.

Battery

While improving the quality and consistency of the battery powder, ultrasound primarily helps to sieve and convey as much good grain as possible in the lowest micron range.

Chemical and Pharmaceutical

Whether for classification, homogenization, dust removal or for the purpose of smooth flow in bulk material handling equipment. In the chemical and pharmaceutical industries, ultrasound helps to optimize powder production.

Paints

Whether in the efficient production and processing of color powder or as a reliable partner for protective sieving in the powder coating process. Ultrasound helps to ensure the required color quality in an remarkably productive manner.

Food

In the food industry, ultrasound helps to optimize the flowability of bulk solids.

Further industries

Whether for classification of batterie powder with sieving machines or for residual cleaning of metal powder from cyclones. Regardless of the industry, Artech helps with ultrasound to achieve the optimal result.

May we help you in finding a solution?

Get in contact with an ultrasonic specialist today.